Are you still opening your process?

When replacing, calibrating and testing measuring devices, it is usually necessary to remove the measuring device , which leads to an interruption of the process. Opening the process is often a challenge and can add complexity, time and cost. In addition, handling sensitive measuring instruments carries the risk of damage or malfunction, which can further complicate the situation. In such cases, efficient solutions are required that minimise downtime and ensure the safety and reliability of the process.

Discover our tailor-made solutions now and optimise your process.

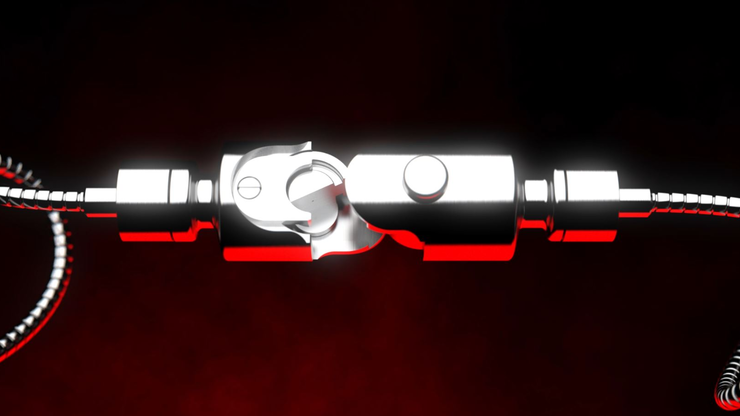

REconnect – Quick coupling device

Safe and leakage-free separation and connection of diaphragm seal systems

The REconnect quick coupling device is welded between the measuring device and the process connection and enables simple and safe disconnection and connection of diaphragm seal systems. Replacing or calibrating measuring devices is therefore no longer a time-consuming and costly procedure and the process does not have to be opened.

- Safe and leakage-free separation and connection of diaphragm seal systems, repeatable many times

- No loss or shifting of filling oil volume or entry of air

- Replacement or calibration of measuring instruments without opening the process

- Autoclavable

- Silicone-free

- Vacuum-proof

- Connecting and disconnecting through removable connecting bracket

- Plant can immediately be put back into operation

- Can be combined with a wide range of Labom measuring devices and diaphragm seals

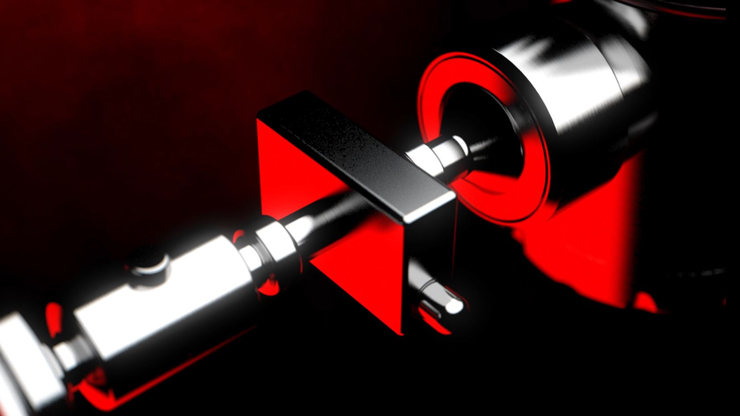

Diaphragm seal testing device

Testing diaphragm seals without opening the process

When testing the function of diaphragm seals, the measuring device and diaphragm seal usually have to be removed. This interrupts the process and, often the bigger problem, opens it up. This can be avoided with the Labom diaphragm seal testing device, which significantly reduces costs and risks.

- Simple procedure for calibrating and testing diaphragm seal systems

- No need to open the process

- System can be put back into operation immediately without cleaning and leckage test

- Detection of deformation and damage to the diaphragm (holes, coating, deformation, corrosion)

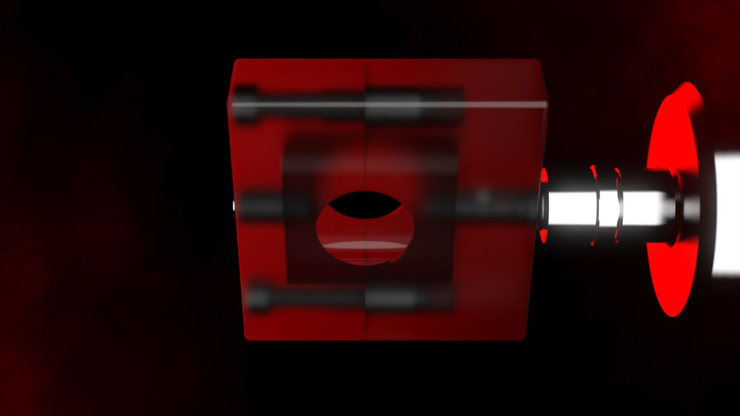

In-Process calibration

Invasive temperature measurement

In this calibration concept, the measurement equipment is designed so that the comparison between measurement device and reference sensor can be performed while installed to the machinery („In-Process calibration“). The certified reference sensor is inserted into a special opening in the device.

- Regular monitoring and checking of several measuring points

- Significantly reduce downtimes

- No need to remove the temperature sensors

Clamp-on technology

Surface temperature measurement

The resistance thermometer in clamp-on technology is used for temperature sensing and process control, mainly for sterile applications in the food and pharmaceutical industry. The resistance thermometer can be quickly and easily fitted to all existing pipework. There are no changes necessary to the piping and no welding required.

- Patented measuring system for hygienic temperature measurement without contact with the media

- Measuring insert can be recalibrated and replaced

- High measuring accuracy and repeatability, fast response time

- System can also be retrofitted

Temperature transmitter GV4

With function package self-monitoring

Optionally, the GV4730 can be supplied with the function package self-monitoring. These devices are equipped with two sensors that monitor each other and offer the possibility of a measured value formation and drift detection. In addition, a drift/failure warning is possible, also via a current pulse in the output signal.