Diaphragm seals

Diaphragm seals are partitions in pressure measuring instruments which prevent the process media from entering the measuring system. This allows them to protect the gauges from aggressive, highly viscous or solidfying process media as well as from high media temperatures, enabling the connection of the instruments to hygienic processes and the reduction of measurement fluctuations and pressure spikes. They also provide relief in case of an unfavourable location of the pressure measurement and enable the use of pressure gauges in potentially explosive areas as well as a measurement arrangement free of dead space.The design of diaphragm seals can vary greatly depending on the measurement task they support: Labom is contributing to precise results and greater operating reliability with patented diaphragm types and customer-specific designs for diaphragm seals.

LTC-Technology

The LTC (Low Temperature Coefficient) diaphragm compensates this temperature-dependent volume expansion of the pressure transmission fluid with a stainless-steel diaphragm. Using a special manufacturing process the mechanically robust stainless-steel diaphragm with a thickness of at least 0.1 millimetres is put into a position between two zero positions and operates in this range with almost no deflection. This allows the diaphragm to absorb volume changes to the fluid due to the influence of temperature so that these fluctuations have practically no effect. Compared to conventional sinusoidal diaphragms, an LTC diaphragm can deliver up to 70 percent greater measurement accuracy.

Fibre laser technology LABtec

To realise special diaphragm surfaces for customers, Labom also develops new manufacturing processes, such as the patented fibre laser technology LABtec. The advantage of "LABtec" is a full-surface diaphragm contact with special material without mix melting or additional soldering connections. This results in a high temperature resistance and stability of material properties (against corrosion, acids, etc.) of the special materials.

Funktion

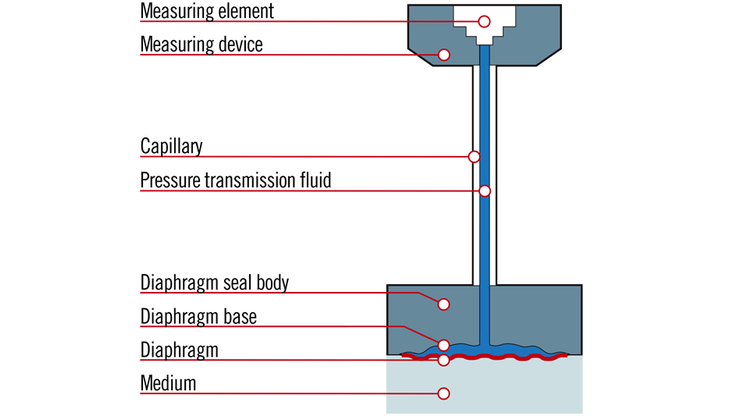

The design of the diaphragm seals can vary greatly depending on the measurement task. Nonetheless, three basic components can be identified on any diaphragm seal.

Particularly important for the protective function of the device is the diaphragm, a thin film that shields the gauge from the media in the process vessel or pipe. The diaphragm is held in place in the diaphragm seal body, which is called the diaphragm body. It must have a suitable process connection so that it can be integrated into the system to be measured. To transfer the process pressure “caught” by the diaphragm to the measurement element, a pressure transmission fluid (diaphragm seal fluid) is used.

Whether the media is problematic, stringent conditions of hygienic applications are given, or the gauges need to be especially robust to vibration, shock or extreme process temperatures – when the measurement task is unusually difficult, diaphragm seals are the perfect tools for the job.

Hygienic Application

Successful customised solutions for challenging use in hygienic and aseptic applications reflect Labom‘s special expertise in this area: Designs with hygienic surfaces and a wide variety of aseptic connections without dead space are available. Labom uses clever techniques, for example extremely reduced volume pressure chambers, which reduce the temperature error to a large degree.

Abrasive Media

For use in highly abrasive media, Labom has developed screw-in diaphragm seals with rubber-coated diaphragms. The rubber coating ensures a long lifetime of the diaphragm for pressure measurements

in areas where solids may be present in the media, such as in mining, or when measuring sludge or fly ash.

Aggressive Media

For use in aggressive media, Labom has developed a particularly robust diaphragm seal made entirely out of titanium, which can be used for the measurement of strongly oxidising or chloride-rich

solutions or suspensions.

Single-Use-Systems

For many other measurement tasks, the challenge lies not so much in extreme environmental conditions and measurement values, but rather in the details. For instance, in the pharmaceutical industry, in addition to process containers made of stainless steel, “single-use systems” are now also used. In these “disposable systems”, the process pressure of flexible plastic bags is recorded, in which the media is prepared. For this demanding challenge, Labom developed a flat diaphragm seal with special diaphragm geometry.

Flat diaphragm seal design

For flat diaphragm seals, the diaphragm lies plane and is usually circular. This facilitates the good spring properties of the diaphragm, thus maintaining low sensitivity of the diaphragm seal to temperature fluctuations.

Advantages

Applications with high accuracy or low pressures, as the flat diaphragm shape has good spring properties. Wide range of assembly options. Can be removed, cleaned or calibrated easily.

Highlights

- Hygienic designs with guaranteed surface roughness values

- Volume optimised diaphragm base

- EHEDG-certified designs

- System fillings for various applications

- Various measuring device connections possible

Inline diaphragm seal design

For inline diaphragm seals, a cylinder-shaped diaphragm is welded into a piece of piping. This ensures the avoidance of turbulence, flow restrictions, dead spaces and other hygienic risks. It must be taken into account, however, that the temperature error may be larger than for flat diaphragm seals.

Advantages

Easy to clean and self-draining. Particularly suited for dead-space free applications, frequent media change, for viscous media.

Highlights

- Basic bodies and flush-mounted membranes made of stainless steel

- Special materials such as tantalum, titanium, Hastelloy, highly vacuum-tight PTFE condenser etc.

- Very low temperature influence

- Filling liquids for various applications

- Various measuring device connections possible

The wide range of applications for diaphragm seals requires a broad variety of solutions. Therefore, Labom has more than 60 standard models in its programme. For hygienic applications they have to comply with the rules of hygienic design with regard to construction, surface quality of the materials and proper cleanability in the scope of CIP/SIP processes.

Matching diaphragm seals

A large number of applications require particularly robust diaphragm seal technology. Here too, the construction and material of the basic body, the diaphragm, the gasket and, if applicable, coatings play a major role. Labom has a wide range of diaphragm seals for use in abrasive, aggressive and highly viscous media or media with high temperatures.

Matching diaphragm seals

STAINLESS STEEL 316L

Stainless steel (1.4404 / 1.4435) is characterised by its generally good resistance and media compatibility. It can even resist weak acids and alkalis, making it the standard material of the pharmaceutical industry.

DUPLEX STEEL

Duplex steel (1.4462) has a high resistance to corrosion cracking in media containing chloride such as pitting. It is well-suited for use in the chemical and petrochemical industry and particularly resistant to seawater.

TANTALUM

Tantalum is the metallic element with the highest general corrosion resistance. With only a few exceptions, tantalum is completely resistant to all pure acids.

TITANIUM

The good corrosion resistance of titanium is based on the formation of a dense and stable protective coating of titanium dioxide. Titanium is particularly well-suited for strongly oxidising and chloride-rich solutions and suspensions. Unlike almost all other common metallic materials, titanium is also resistant to chloride-saturated solutions.

HASTELLOY

The nickel-based alloy Hastelloy is very resistant to crevice and pitting corrosion and corrosion cracking and is resistant to chlorides, mid-concentrated sulphuric acids, acetic acids and phosphoric acids.

MONEL

Monel is a nickel-copper alloy with a good resistance to strong alkalis, most salt solutions, seawater as well as diluted and mid-concentrated inorganic acids.

NICKEL

Nickel is well-suited for application in strong alkalis such as sodium hydroxide or potassium hydroxide.

Further materials upon request.

Gold

As a precious metal, gold has a very low reactivity. It is particularly suited for hydrogen applications, as a gold coating acts as a di.usion barrier.

PFA

This plastic is used in adhesive media becaus of its excellent anti-adhesive properties. It is also resistant to practically all chemicals and suited to a temperature range from – 40 to 260 °C.

PTFE

In addition to excellent anti-adhesive properties, this plastic is characterised by its very good resistance to strong alkalis and acids. Special designs for vacuum applications up to 200 °C are available, in the overload pressure range PTFE can be used from - 20 to 260 °C.

Rubber Coating

A rubber coating protects the diaphragm from sharp objects and is consequently used in the cement industry, for instance.

Nanofinish

Contour-mimicking and infiltration-resistant non-stick coating (thin film) with enhanced corrosion protection. Nanofinish is FDA-conform and silicone-free - also di.usion-resistant and therefore usable for water vapour.