SIL

Any technical installation carries a risk – this is smaller or greater depending on the application. Measuring devices can help to control the risk as part of the safety system. To do this, they must be particularly reliable.

Measuring devices that are developed and manufactured in accordance with SIL (DIN EN 61508) meet particularly high demands in terms of fail safety. SIL stands for Safety Integrity Level and takes into account the failure rates of the devices used.

But how is a measuring device actually qualified for SIL?

In order to qualify measuring devices in accordance with the SIL standard DIN EN 61508, numerous organisational measures, control mechanisms and software requirements – if applicable – must be met in the background. In addition, it is essential to determine the functional safety values. These are incorporated into the calculations for the functional safety of the system operators. There are two ways to determine the values.

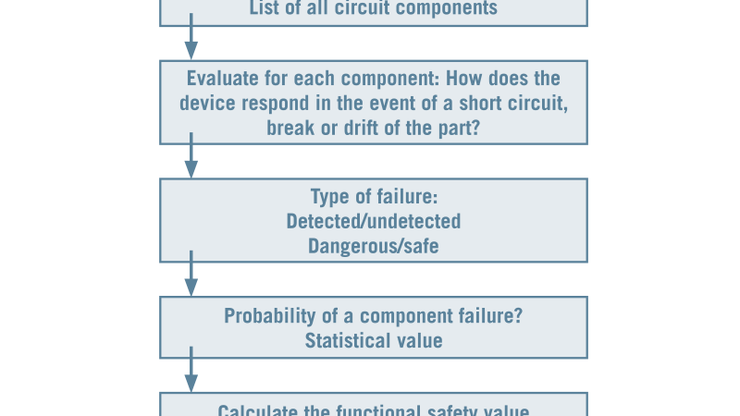

Determination of the functional safety values through FMEDA

In an FMEDA (Failure Modes, Effects and Diagnostics Analysis), all components relevant for the safe operation are recorded. The consequences of a failure are then checked for each individual component. A distinction is made between

• Open circuit (= connection in the circuit breaks)

• Short circuit

• Drift

For each of these possible errors, a check is carried out to determine how this changes the behaviour of the measuring device. Does it continue to take measurements? Does it stay within its assured accuracy? Is there an impact on response times? The effects can be used to determine whether the failure is dangerous (affecting the safe function) or safe (not affecting the safe function).

A check is then carried out to determine whether a component failure would be detected – because a system can respond to detected errors, the main problem is undetected errors.

In order to assess the probability of a component failure, it is possible to draw on appropriately published empirical values or on information from the manufacturers.

With these considerations, the basis for calculating the values of functional safety in accordance with DIN EN 61508 is now provided – for example, the rates of dangerous failures, the probability of failure on demand (PFD) or the proportion of safe failure fraction (SFF).

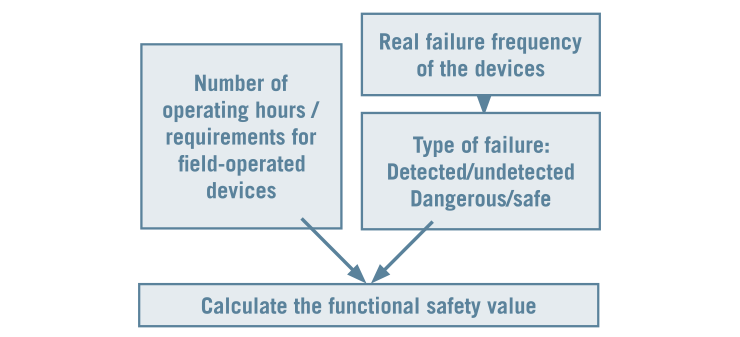

Determination of the functional safety values through operational reliability

Operational reliability is based on experience with a large number of devices that are already in use. DIN EN 61508 specifies the minimum number of operating hours or requirements of the safety function that must be achieved in order to meet the requirements for operational reliability. Data on operating hours in the field and any errors that may have occurred (this will not be many …) are specifically evaluated. Any possible errors that are observed are divided into safe and unsafe, detected and undetected. This data is then the basis for calculating the values of functional safety in accordance with DIN EN 61508.