Made to measure

Labom's product catalogue is becoming more comprehensive every year – but we offer more than just the standard devices in the catalogue. You can also find customised solutions: together with our customers, our engineers develop temperature and pressure transmitters that are specially tailored to the customer’s own systems and requirements. Whether process connection, displays or measuring range: numerous features of the instruments can be individually adapted. Especially in the field of hygienic process connections, Labom has a wide range of options thanks to its many years of expertise. In addition to existing process connections, completely new, tailor-made connections can be created. Should it happen that our portfolio does not contain the required options, it is most likely that we will develop a completely new device. We are happy to be inspired by our customers and together we will find new solutions that move the industry forward. Special challenges such as unusual measuring ranges, extreme conditions or tricky questions inspire us – this is how we create new solutions made to measure together with our customers again and again!

If it should happen that our portfolio does not contain the desired options, it is quite possible that we will develop a completely new device. We like to be inspired by our customers and together we find new solutions that move the industry forward.

Special challenges such as unusual measuring ranges, extreme conditions or tricky questions inspire us – this is how new customised solutions are always created together with our customers.

One process connection for two measuring ranges

This customised solution was developed for an individual customer requirement from the pharmaceutical industry, a level measurement in a container. The application requires a very high measuring accuracy, and that with significantly varying pressures and a wide temperature range at only one measuring point.

The solution is to use two pressure transmitters with different measuring ranges, both mounted on a diaphragm seal. Depending on the point in time in the process and the filling level in the container, this system can change from a higher measuring range of up to 4 bar to a smaller measuring range of up to 400 mbar, and this with the highest measuring accuracy in each case. The smaller measuring range is also overload-proof and the sensor is insensitive to the higher pressures. To achieve the high measuring accuracy with temperature fluctuations, the diaphragm seal was additionally designed with our patented LTC diaphragm. The LTC diaphragm (LTC = Low Temperature Coefficient) compensates for temperature-related volume expansions of the filling liquid with a specially shaped stainless steel diaphragm and increases the measuring accuracy by up to 70 percent.

Two is safer than one

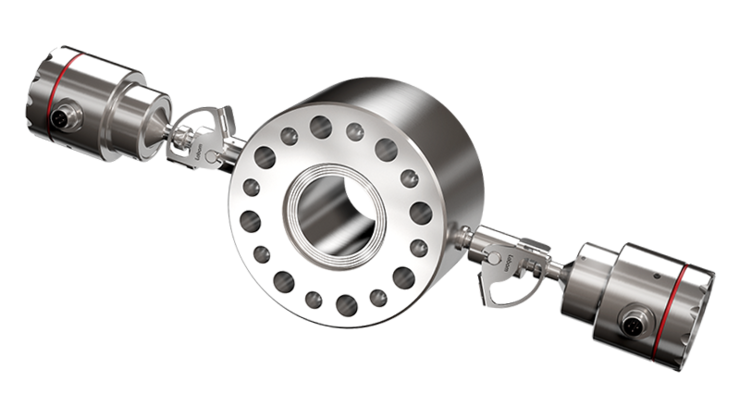

A customised solution was developed for an application in the food industry. The customer required a very special flange diaphragm seal connection for measuring pressure in its process, which no other manufacturer was willing to produce for them at that time. Another requirement was for redundancy of pressure measurement at its plant.

To solve this, Labom designed and manufactured a customised diaphragm seal for various nominal pipe sizes of 1“, 2“, 3“ and 4“, upon which two PASCAL CV4 pressure transmitters were connected to the process using a REconnect quick coupling. This meant that the pressure was measured at two points simultaneously, resulting in the system effectively checking itself. With REconnect quick couplings it is possible to easily and safely disconnect measuring devices without having to halt and open the process. In this way, one PASCAL CV4 transmitter could be disconnected from the system and recalibrated without pausing operation. While this is done the second transmitter continues to measure the pressure and transmit values to the system control unit. This ensures safe and continuous operation.

Kombibar: Single process connection – dual benefit

Labom realised for many customers tailor-made solutions for their very specific measurement tasks. One of the favorite solutions are "Kombibar" devices: in one measurement point two different measurement methods are combined.

Typically, the “Kombibar” devices by Labom are equipped with a mechanical on-site indicator, which ensures permanent indication – quick and easy – and requires only one process connection. The pressure transmitter delivers highly precise data that can be recorded and analysed in the plant control system.

Using a corresponding adapter, a wide range of variations - also with additional features - can be realised. If required, further functions can be added such as an additional switch function for safety shut offs if a certain pressure limit is detected. To meet hygienic requierement in the food industry the combination with hygienic diaphragm seals is possible. In paint shops the use of silicone free fill liquids have proven success and in gas and oil industry diaphragm seals suitable for high pressure peaks are the choice.

For every measurement task a suitable combination can be found.